Water analysis in the food and beverage industry

Food producers are faced with the challenge of ensuring the quality of their products, complying with environmental regulations and ensuring cost-efficient processes at the same time. The use of Total Organic Carbon (TOC) measurement technology offers you a range of benefits in various applications within the food and beverage sector. Here are the key benefits you can realize by using TOC measurement technology.

The use of TOC measurement technology in the food and beverage sector offers a wide range of benefits, including efficient environmental monitoring, quality control, resource conservation and maximum plant availability. By integrating this technology, you can optimize your operating processes, reduce costs and at the same time ensure the highest quality standards for your products.

Serviceliste

-

Efficient environmental monitoring and compliance with regulationsListenelement 1

TOC measurement technology allows precise monitoring of the organic carbon content in wastewater, enabling effective compliance with environmental requirements and regulations. You can ensure that your wastewater treatment plants are operating optimally and minimize the discharge of harmful substances into the environment.

-

Optimization of process automation and quality assuranceListenelement 2

Continuous online monitoring using TOC measurement technology allows you to automate your processes and optimize operating procedures. This enables precise control of water quality and helps to ensure product quality.

-

Saving water and conserving resourcesListenelement 3

The precise analysis of TOC contents enables you to save water and conserve resources. You can optimize water consumption and reduce water disposal costs at the same time.

-

Efficient cleaning processes and validationListenelement 4

TOC measurement technology supports you with clean-in-place (CIP) process control and cleaning validation. You can ensure that your cleaning processes run efficiently and that the cleanliness of your systems is guaranteed.

-

Predictive maintenance for maximum system availability

By integrating predictive maintenance strategies, you can identify potential failures at an early stage and plan planned maintenance measures efficiently. This minimizes unplanned downtimes and maximizes system availability.

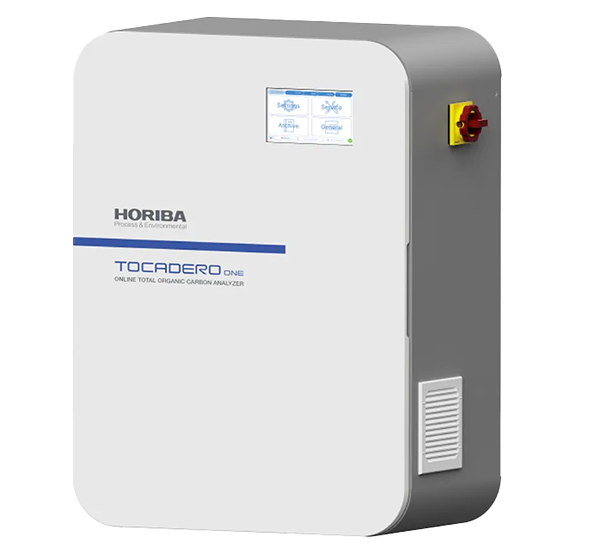

The Tocadero ONE is a modern, low-maintenance TOC analyzer that combines maximum precision, efficiency, and user-friendliness.

High-temperature combustion at 1,200 °C without a catalyst enables complete oxidation of even stable carbon compounds—directly in the process, in real time, and under the most demanding conditions. Developed as a flexible yet highly precise online analyzer, it is used in many areas. Also available in an Ex version.